History

From Garage Space to Aerospace, Bomco Celebrates 60 Years of Excellence.

If there is one link in the interesting 60 year history of Bomco,inc. it is the pursuit of excellence. It started in 1958 as a part-time operation in a small garage belonging to Jim MacFeeley and a company named Bomco Pressed Metal and Spinning. One of their early customers, a young man named Pete Banks, needed “pail extensions,” special funnels, and refurbished spools for the wire processing operations of the Warren Wire Co. of Pownal, Vermont. While Banks was unimpressed with Bomco’s building, drill press, small jigsaw and three old small lathes, he was most impressed with the quality and excellence of their unique “metal spinning”. (A technology well known by the ancient Egyptians but not taught in Bank’s engineering classes at Cornell). In fact, the wire spools were beautifully refurbished and ran truer than when new, a first in the wire industry.

If there is one link in the interesting 60 year history of Bomco,inc. it is the pursuit of excellence. It started in 1958 as a part-time operation in a small garage belonging to Jim MacFeeley and a company named Bomco Pressed Metal and Spinning. One of their early customers, a young man named Pete Banks, needed “pail extensions,” special funnels, and refurbished spools for the wire processing operations of the Warren Wire Co. of Pownal, Vermont. While Banks was unimpressed with Bomco’s building, drill press, small jigsaw and three old small lathes, he was most impressed with the quality and excellence of their unique “metal spinning”. (A technology well known by the ancient Egyptians but not taught in Bank’s engineering classes at Cornell). In fact, the wire spools were beautifully refurbished and ran truer than when new, a first in the wire industry.

Recognizing both the high quality of metal spun parts and their future potential, Pete Banks not only gave Bomco more orders but decided to buy into the company! The owners accepted immediately and the new partnership began. (The initials of the original partners, Bunker, Oberg, and MacFeeley, formed the basis of the name, BOMCO.)

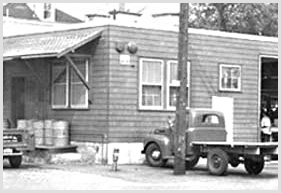

In the meantime, making the first move of many to expand and improve operations, Bomco bought the Stoddard Machine Shop building on Main Street in Gloucester in 1959. Incorporating in April of 1960, Bomco began its expansion and technology phase. As the Gloucester Daily Times reported “Expansion is taking place so rapidly…that the company is about to burst right out of the old barn.”

Bomco’s technical development was booming as well with production of a doppler guidance reflector for the Hawk missile and parts for the Sparrow missile. But burst the barn it did.

In April 1964 Bomco moved to a refurbished facility at the site of the old GMI laundry on Burnham Street in Gloucester. With 7,000 square feet and almost 50 people, Bomco was able to develop and diversify the business. During this “Burnham Period” of 1964-1968, Bomco again focused on excellence and technology. Taking on a difficult glass-to-metal seal project for Sylvania, Bomco not only earned two patents but secured a niche in the high tech market of lasers, electro-optical, and thin film deposition products. At the same time, Bomco engineers refined the metal spinning technology to produce components for a line of vacuum diffusion pumps for Varian Associates.

By January of 1968 the Bomco facility was again bursting at the seams, and a well-planned move was made to a newly-built 16,000 square foot Armco steel building on Gloucester Ave., just off Route 128. During this “new plant era,” Bomco solidified, supported and developed its core businesses. New England Metal Spinning, purchased in December of 1973, was integrated into the plant during 1989 and 1990. Three additions were made to the main plant and a second manufacturing facility built across the parking lot. The core businesses of metal forming, glass-to-metal seal assemblies and wire processing products were supported by the latest technologies and equipment.

Today Bomco is a registered ISO 9001/AS 9100 company with almost 100 employees operating in a 52,000 square foot facility. It uses state-of-the-art parametric modeling, multi-axis laser machining, CNC machining, CNC plasma cutting, CNC expanding, CNC spinning and hydraulic forming.

The thread of excellence that started with refurbishing wire spools now extends to such products as a “bulge seal” for the jet engine of the joint strike fighter and to the ultra high vacuum window allowing visual access to the thin film deposition process. Bomco will continue to earn its corporate motto, “Excellence in Metal Forming” with the many customers and industries it serves.